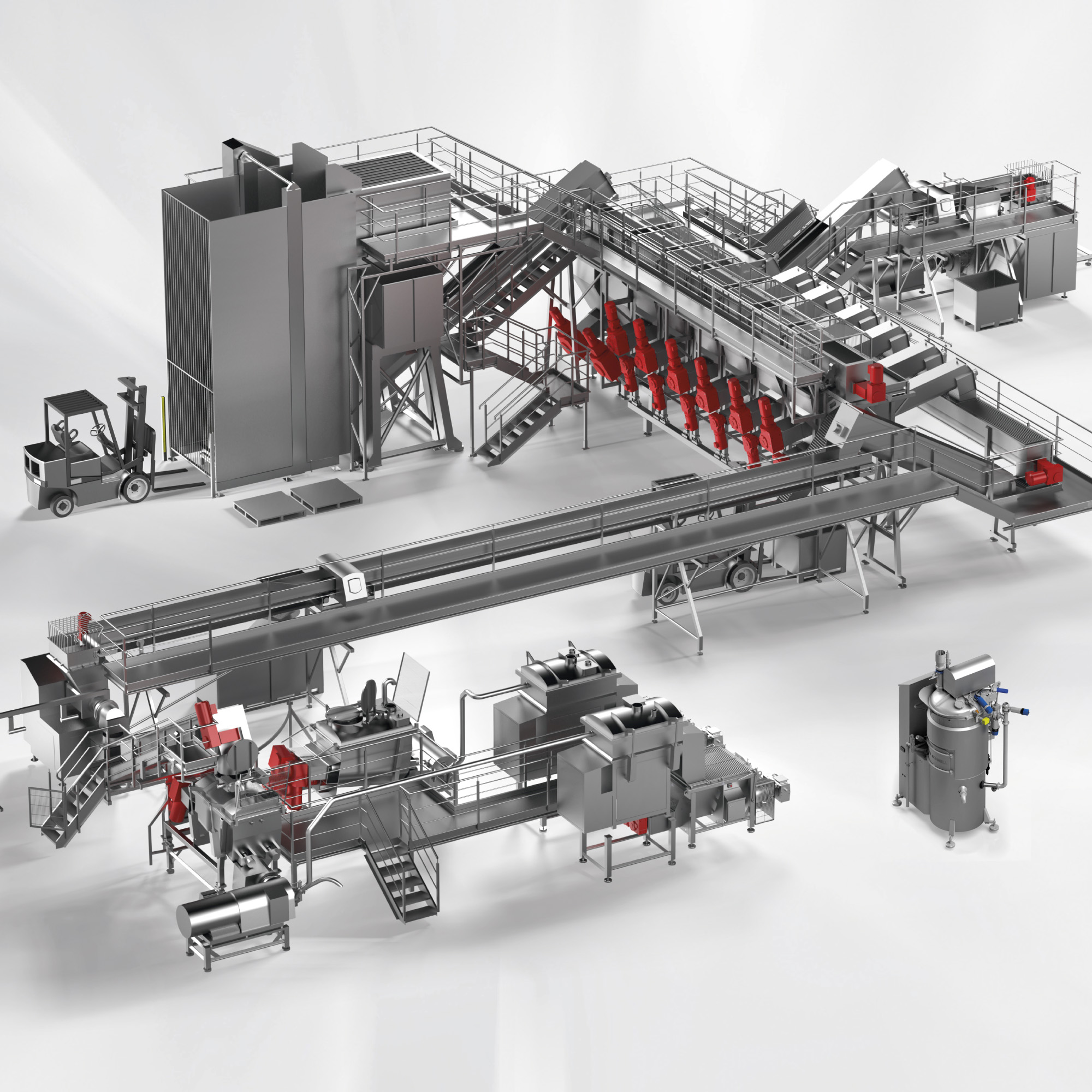

Founded in 1964, PFM is an international industrial group that is a benchmark in the design and manufacture of flexible packaging for the food and non-food industries: food (fresh and dry products, confectionery, bakery products, dairy products, pasta, meat, frozen foods), chemical-pharmaceutical, cosmetics, beverages, pet food, detergents and wet wipes, always ensuring high standards of quality, safety and reliability. This wide versatility allows the Group to offer customised packaging solutions, suitable for every type of product and production process.

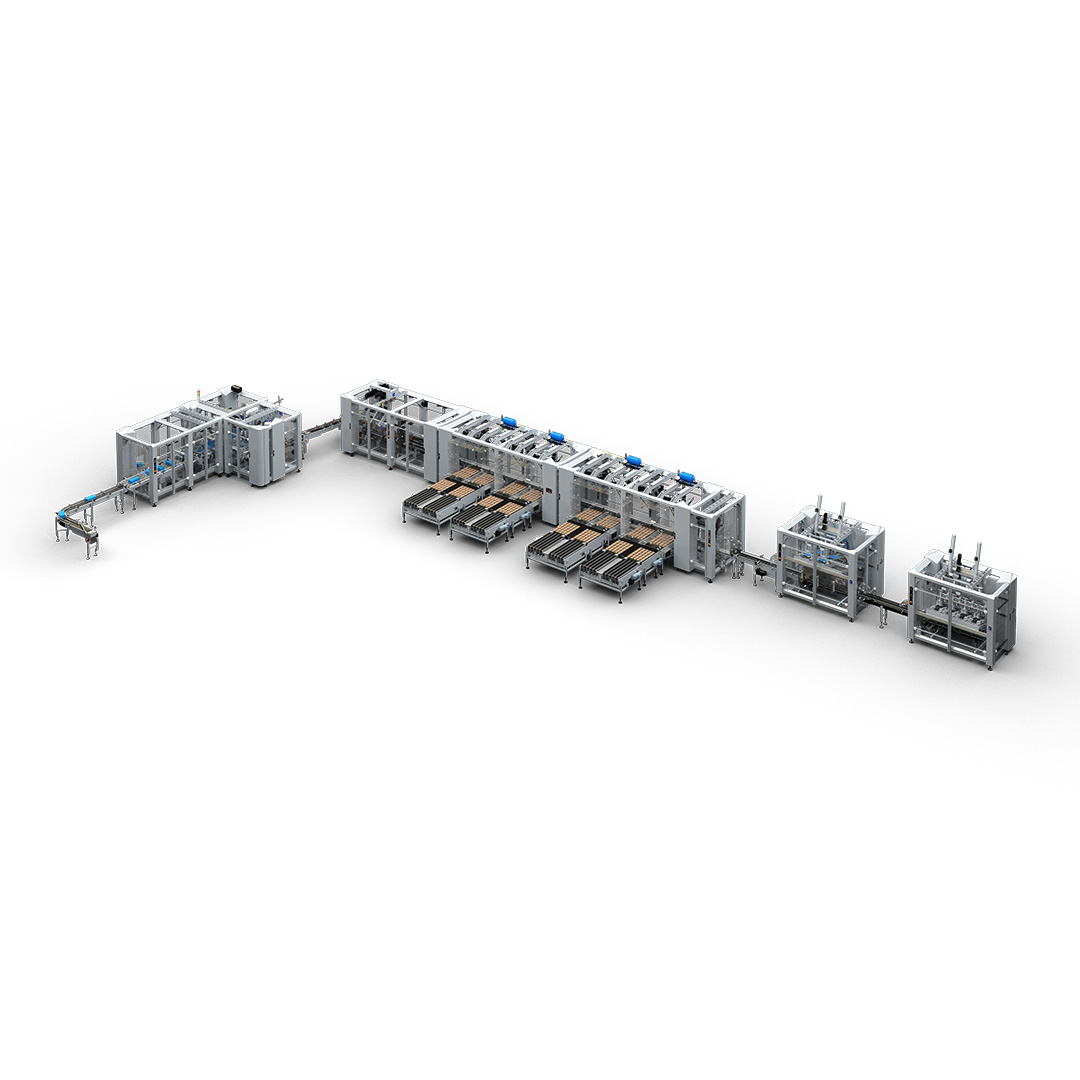

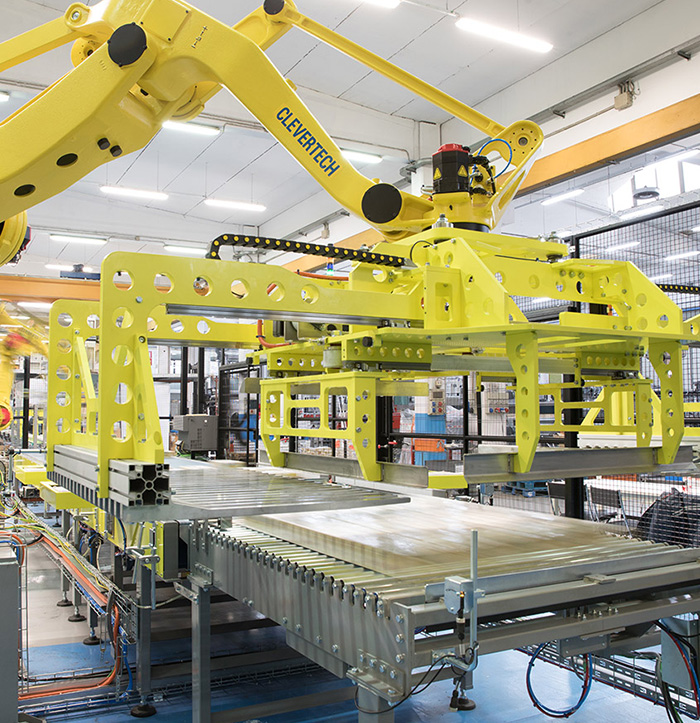

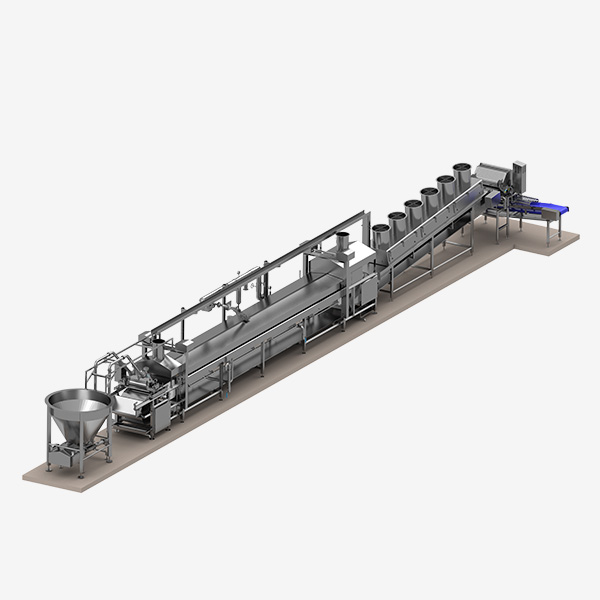

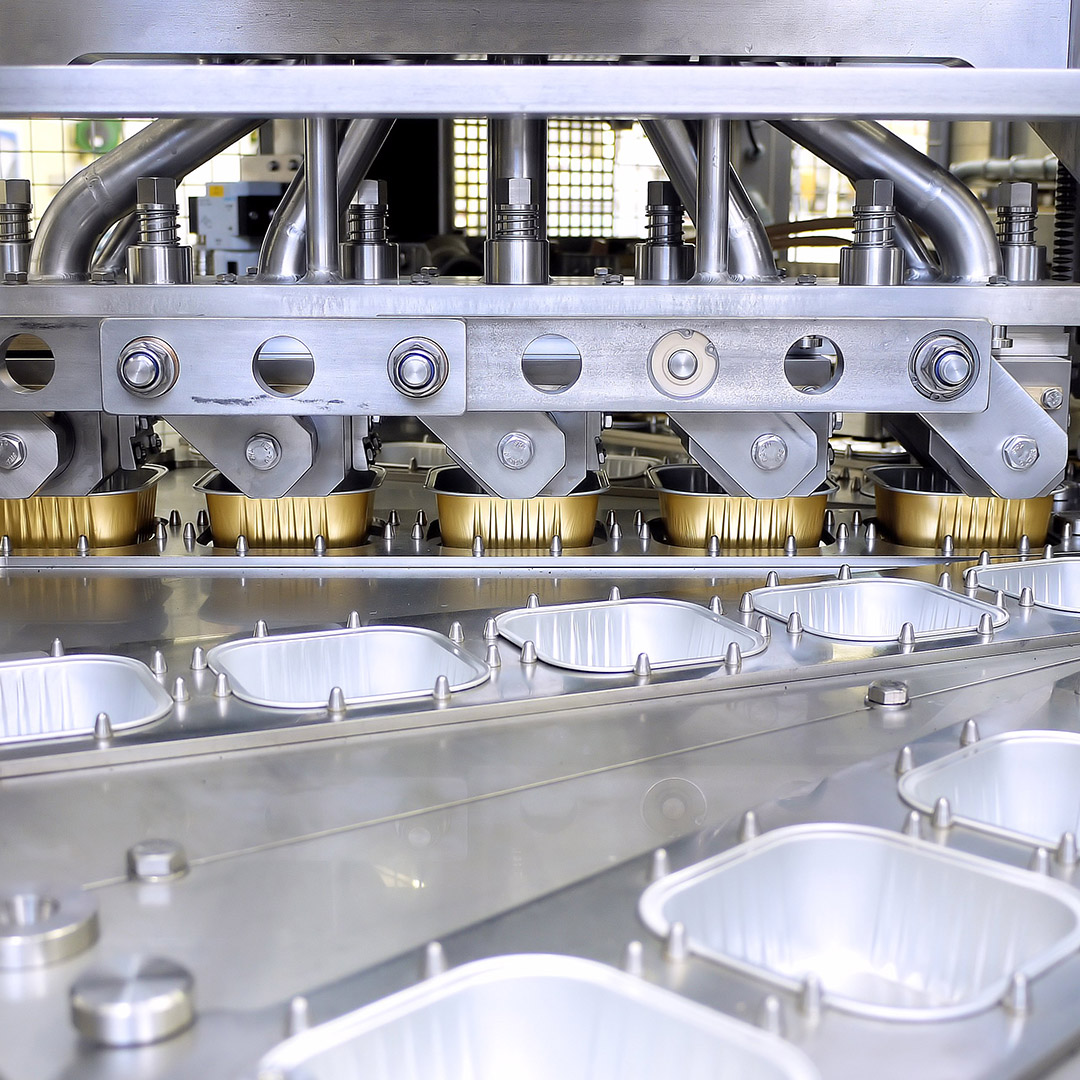

P.F.M. S.P.A. is the parent company of the PFM Group and represents its operational and strategic hub. Based in Torrebelvicino (Vicenza), it coordinates the activities of the 14 specialised companies that make up the Group, located in Italy, the United Kingdom, Germany, Spain, Canada, the United States and Thailand, providing administrative, technical and commercial support and ensuring consistency and synergy in industrial and commercial processes at a global level. The headquarters is also the technological and production heart of the company, where advanced packaging solutions are designed, built and marketed, including flowpack and form fill & seal packaging machines, as well as a wide range of automatic packaging and feeding systems.

The product portfolio includes around 40 different models of packaging machines, as well as numerous customisable accessories, designed to meet specific customer requirements in terms of format, product, performance and automation.

The PFM Group’s leadership is the result of substantial investment in research and development, continuous and constructive dialogue with end users in its areas of expertise, and its ability to internationalise and conquer new markets.

With an extensive sales network covering 70 countries worldwide, a dedicated team of Area Managers PFM coordinates an active sales network that guarantees customers fast, efficient and personalized service, mainly in Europe, North and South America, the Middle East and the Far East. Over the years, the Group has built an integrated and technologically advanced industrial ecosystem capable of responding to the needs of increasingly diverse and competitive markets. The companies in the group design and manufacture packaging machines, complete lines, multi-head weighers, high-precision dosing systems and tailor-made solutions in-house, ensuring high quality standards, innovation and reliability.